What is energy from waste?

In recent years, the issue of waste disposal has become a growing problem. Across the globe, countries are keen to find alternative solutions that reduce the amount of waste being sent to landfill sites. One such popular solution is waste-to-energy incineration plants. These facilities can transform non-recyclable waste into electricity and heat, helping to reduce our dependence on fossil fuels while cutting down on our environmental footprint.

Waste to energy, or WTE for short, is a process whereby waste is converted into usable energy. This is achieved through the burning of non-recyclable materials in an incinerator plant. The heat generated from this combustion process then drives turbines connected to generators which produce electricity and other forms of energy. Waste incinerators are designed to burn combustible materials such as paper, plastic, domestic waste, industrial and agricultural waste etc. In addition to producing energy, these plants also reduce the volume of waste that requires disposal by up to 90%.

When operated correctly and under strict regulations, modern day waste incineration plants can be very efficient in terms of both energy production and reduced carbon emissions. Several different types exist including Fluidised Bed Incinerators (FBR), Multiple Hearth Furnaces (MHF) and Rotary Kiln Systems (RKS). Depending on their size and design they can generate anywhere from 1MW – 200MW of electrical power or steam for heating buildings etc., with many harnessing their heat output for combined cooling & heating systems (CCHP).

Types of Waste Incinerator Plants

Waste incinerator plants are used to dispose of a variety of waste materials. They are most commonly used to reduce the volume of solid waste, including medical and hazardous wastes, industrial sludge and other combustible materials. The plant can increase energy efficiency while reducing pollution and meeting environmental regulations.

Incineration is considered one of the most efficient ways to dispose of non-recyclable waste because it reduces the amount of space required for storage by up to 90%, as well as drastically reducing the number of landfills needed due to its ability to burn trash at high temperatures. There are several types of incinerator plants available: mass-burn systems, refuse-derived fuel (RDF) systems, co-incineration facilities, cement kiln systems, and pyrolysis systems.

Mass-burn systems use an open combustion chamber where materials are burned in large batches before being released in air emissions via scrubbers or filters which capture molecules from flue gas that may be harmful pollutants. RDF systems convert municipal solid waste into a combustible fuel that can then be burned in power plants or cement kilns for heat generation or electricity production without producing smoke or odors. Co-incineration facilities use multiple fuels such as natural gas, wood chips, sawdust, coal etc., combined with municipal solid waste for burning purposes in order to generate energy more efficiently than using only one type of fuel source alone.

Benefits of Waste Incinerator Plants

Waste incinerator plants have many advantages over traditional landfill sites. First, they offer a much more efficient way to dispose of non-recyclable waste materials. Instead of taking up space in landfills, the incinerator plant can reduce these materials to ash which is then disposed of responsibly and with minimal environmental impact. This not only helps reduce the amount of waste going into landfills but also eliminates any potential hazardous material that may be contaminating the environment.

Another benefit is the production of energy from burning this waste. With modern technology, it is possible to convert some of the heat generated by burning waste into electricity for use in homes and businesses. This helps to reduce reliance on fossil fuels as well as provide an alternative renewable source of energy for communities who are unable to access traditional power grids.

Finally, these plants can help improve air quality due to their ability to filter out pollutants from emissions before they are released back into the atmosphere. This means that local residents can enjoy cleaner air without having to worry about toxic air contaminants being released into their environment, providing an added layer of protection against pollution-related illnesses and diseases.

Potential Environmental Impacts

The potential environmental impacts of waste to energy facilities are numerous and can be both positive and negative. Incineration is highly efficient, meaning less waste is produced, but also produces air pollutants that must be controlled. Incinerators release greenhouse gases such as carbon dioxide (CO2) into the atmosphere which contribute to climate change. They also produce particles such as fly ash that can contain heavy metals and other toxic substances which are hazardous to human health if not managed properly. Waste incineration plants typically have high levels of odours from burning waste, something that has been shown to cause annoyance and discomfort for nearby residents. Furthermore, wastewater from these facilities needs to be treated before being released back into the environment, as it may contain harmful pollutants that could contaminate local soil or water sources if not managed correctly. Finally, ash produced by the incinerator must be stored in landfills or recycled appropriately in order to avoid releasing leachates into the air or water sources near the facility.

Want to hear more?

Or call us now!

Regulations & Best Practices

The regulations and best practices surrounding waste to energy in the form of incinerator plants are expansive and often complex. Every facility must adhere to all federal, state, and local laws related to air quality control, water discharge, hazardous materials storage or disposal, worker safety and more. Waste incinerators must also be designed with an effective emissions control system that meets US EPA guidelines for air pollutants such as mercury, particulate matter (PM), sulfur dioxide (SO2) and nitrogen oxides (NOx). Additionally, best practices include procedures for protecting public health from potential exposure to toxic pollutants through proper emission monitoring systems. Waste incineration should be conducted in accordance with the highest standards of safety protocols and emergency preparedness in order to reduce risk factors associated with operating a hazardous waste site. Finally, operators should continually strive towards improved efficiency by regularly assessing plant performance against industry benchmarks.

Technological Improvements

Technological improvements in waste to energy plants have been significant over the past several decades. Incinerator plants are now much more efficient, producing higher amounts of energy from the same amount of waste material than ever before. In some cases, it is even possible to produce electricity directly from burning garbage and other materials. This process is known as “direct combustion” and can be used to generate both power and heat energy. Additionally, newer technologies are being developed that allow for greater efficiency in the incineration process itself. For example, systems that use advanced air filters can reduce harmful emissions by up to 80 percent while simultaneously increasing fuel efficiency. These kinds of technological improvements allow for a much cleaner form of energy production than traditional methods such as burning coal or oil.

Conclusion: Promising Future

The conclusion that can be drawn from the use of waste incinerator plants is that it has a promising future in terms of being able to provide energy, create jobs and reduce the amount of waste going into landfills. The technology used in these plants is becoming more efficient and cost-effective, making them an attractive option for cities looking to reduce their environmental impact. Additionally, advancements in technology are allowing incinerators to capture more pollutants, reducing their environmental impact even further. With continued research and development, there is potential for waste incinerator plants to become a major source of energy production.

With more countries beginning to focus on renewable alternatives such as wind and solar power, incineration could help bridge the gap between current levels of energy consumption and renewable sources. Additionally, with better technology comes better control over emissions produced by these plants which could make them a viable alternative in densely populated urban areas. By utilizing this type of energy source responsibly, the promise offered by these plants can be realized while minimizing any negative impacts on our environment or health.

Why Winno Energy?

In the United Kingdom, there are many providers of industrial biomass boilers available. These specialize in supplying high quality systems with advanced technology to businesses across all industries.

The best providers offer unparalleled customer service and expertise in helping clients choose the right system for their needs. They also ensure that every installation is completed efficiently while meeting all safety standards and regulations.

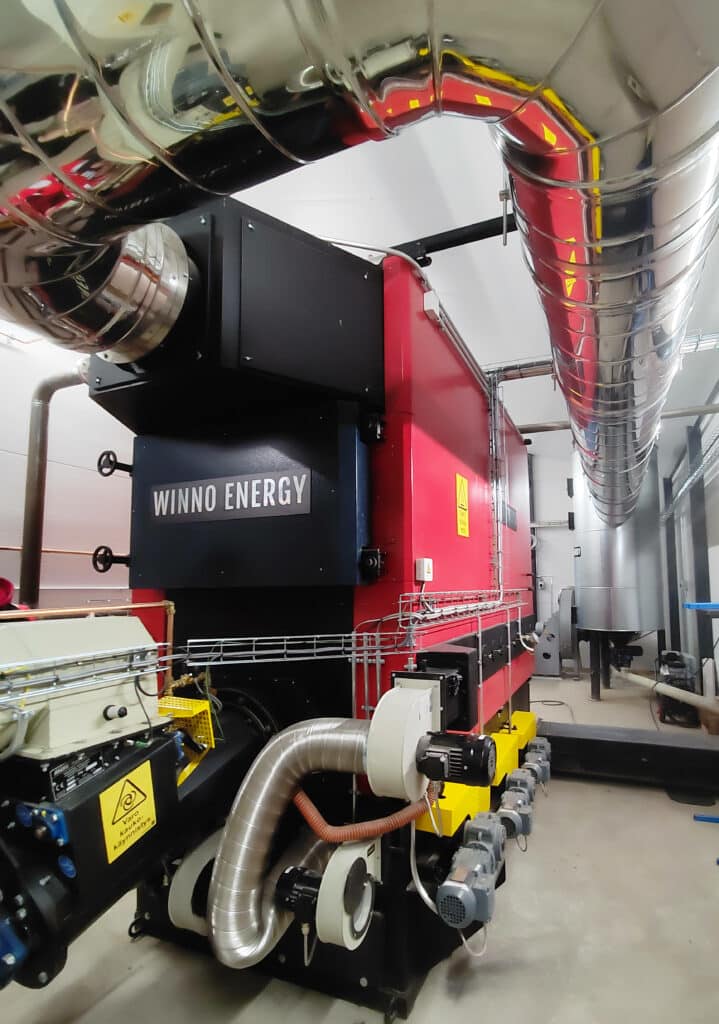

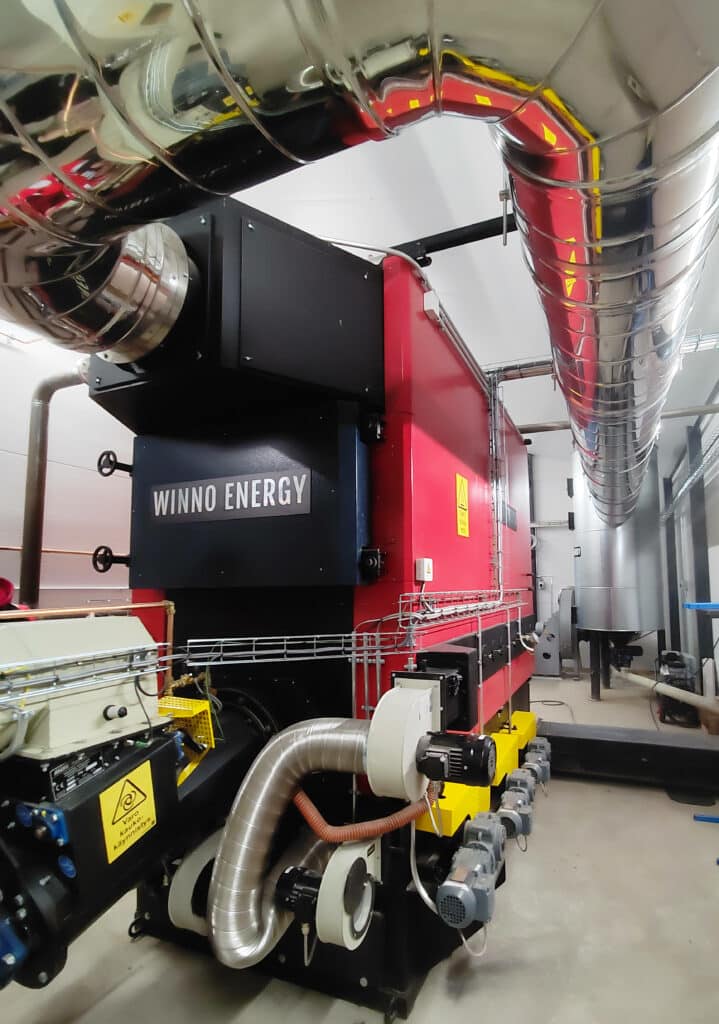

Winno Energy has many years of experience in designing and supplying a wide range of biomass boiler plants in United Kingdom.

Winno Energy not only supplies boiler plants in a range of sizes and variants, we also have vast experience in this sector and ability to design and configure biomass plants that match your requirements and fully comply with design standards.

Unlock the potential of renewable energy now! Our experts in Winno Energy have decades of experience in the biomass and waste to energy industry – so why wait any longer?

Click the yellow button or fill the form below

Below listed all regions where Winno Energy provides biomass boiler services: East Midlands Eastern Isle of Man London East Midlands Eastern Isle of Man London North East North West Northern Ireland Scotland South East South West Wales West Midlands Yorkshire and the Humber